“Design is not just what it looks like and feels like.

Design is how it works.”

MACRO MANAGEMENT

When working for the German-Japanese tech concern TDK Electronics, I've been involved in projects for optimizing internal processes. One of them was setting up a matrix in Microsoft Excel for quality assurance, providing the possibility of highlighting problems within the production line of Hongqi, China. Here, employees control arrays with produced bobbins, and record damaged pins using the matrix regularly. In this case, one array contains 10 x 16 bobbins with two pin sides each, so 320 configurable states in total. After saving the results, the tool returns an evaluation of all registered arrays to point out critical spots. This visualization shall help the company with adjusting machines from the production line correctly, therefore reducing waste and costs. This file uses Macros/ VBA code and input masks to improve functionality and usability.

Simplified input through masks

Matrix with dropdown lists, info and support masks

By selecting one pin side of a bobbin, the user can enter if the spot was produced flawlessly or not. After all states have been set, Excel checks the matrix for invalid values before giving you the chance to transmit the new data to one of the production line’s data banks. This information is then being used to show overall quality performances of each line on a separate sheet.

Analyses visualized as graphs for performance reviews

Macro control

Visual Basic for Applications (VBA) is a language for controlling processes within Office applications by Microsoft. It can help out tremendously with optimizing the usage of related files, in this case by Excel. Without VBA, these project results would have turned out

less functional and beneficial.

LEVEL DESIGN - CREATION OF WORLDS

1 | SOURCE ENGINE

Fascinated by today’s video game level design, I was wondering how difficult it is to build a "world" by myself.

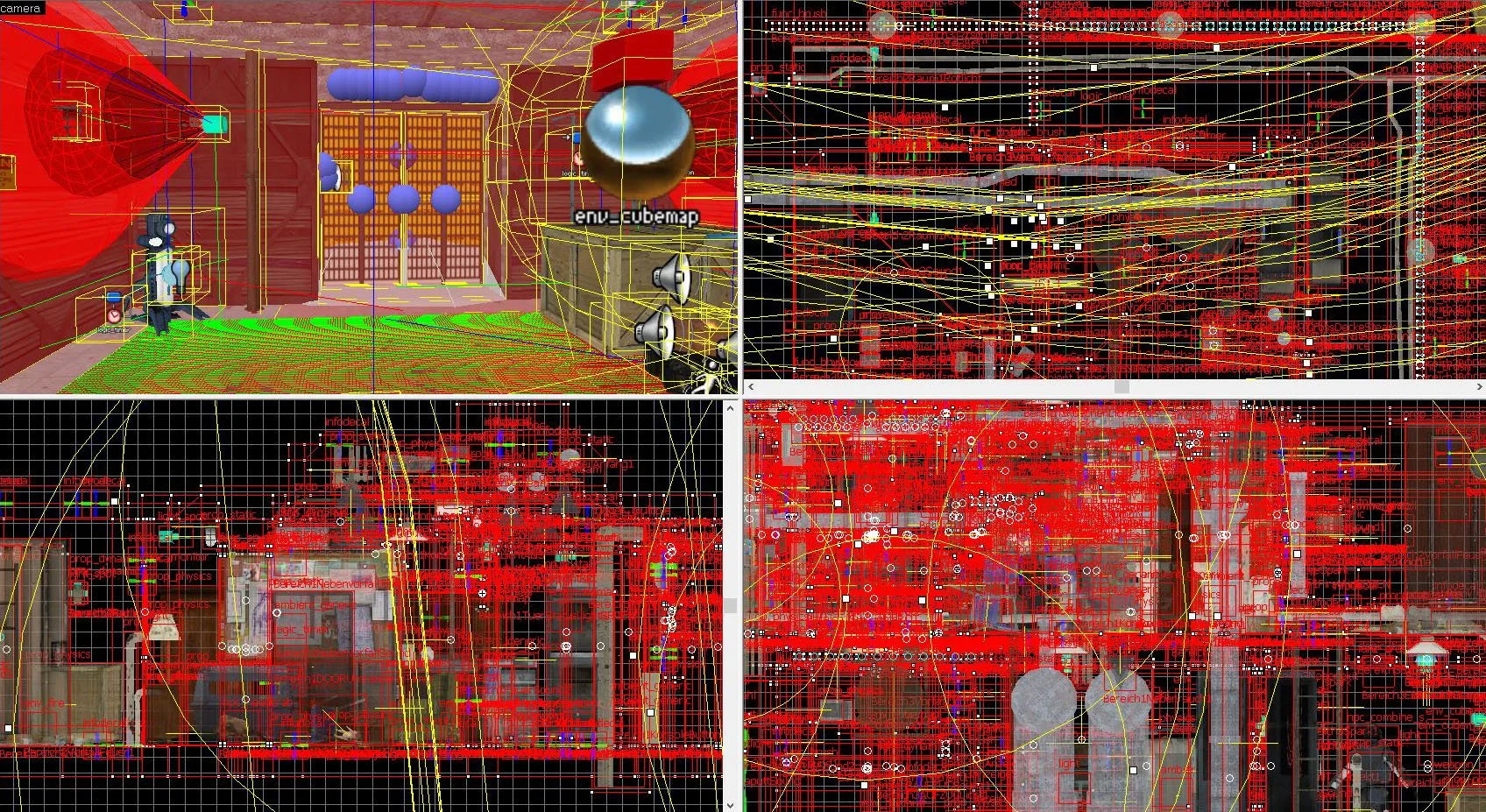

To get started, I used the very successful game engine Source by Valve as a blank sheet to work with. Valve’s more unknown Hammer Editor became my tool with which I intended to build the world, plus to set all triggers and special effects for some intense game play. It didn't took me long to figure out what I will need the most of: Patience.

Hammer is well-conceived, nevertheless, you still feel the same as when you open a complex program like

Adobe After Effects for the very first time: You just don't have a tiny clue how to get started.

The ultimate

puzzle

It took me hours just to build a normal, very minimalist square room with a simple light switch correctly without drowning in error messages. Every object, effect, sound, light, texture, every single entity needs to be adjusted - Sometimes holding a hundred properties individually.

Tutorials and online manuals are essential to get a grip onto this editor.

For almost half a year, I set over 5,000 entities manually. My personal conclusion is, that it truly is difficult and confusing at first, but only time consuming at last designing your own video game world. It sounds frustrating, however, I had much fun implementing a playable scenario, and it is indescribably satisfying to see the final product in the end just as you wished for.

Again, patience is the key – And gallons of coffee.

Blank in Orange

How a new level room looks without any textures, entities or formations: Everything which might make this orange blank sheet more interesting has to be set, adjusted and shaped by “hand”. Since this takes much time, it can be smart to plan the design and action beforehand.

WATCH HOW MY WORLD LOOKS IN MOTION:

⚠ Viewer discretion is advised !

2 | RENDERWARE ENGINE

Promotion of mod features for German audience

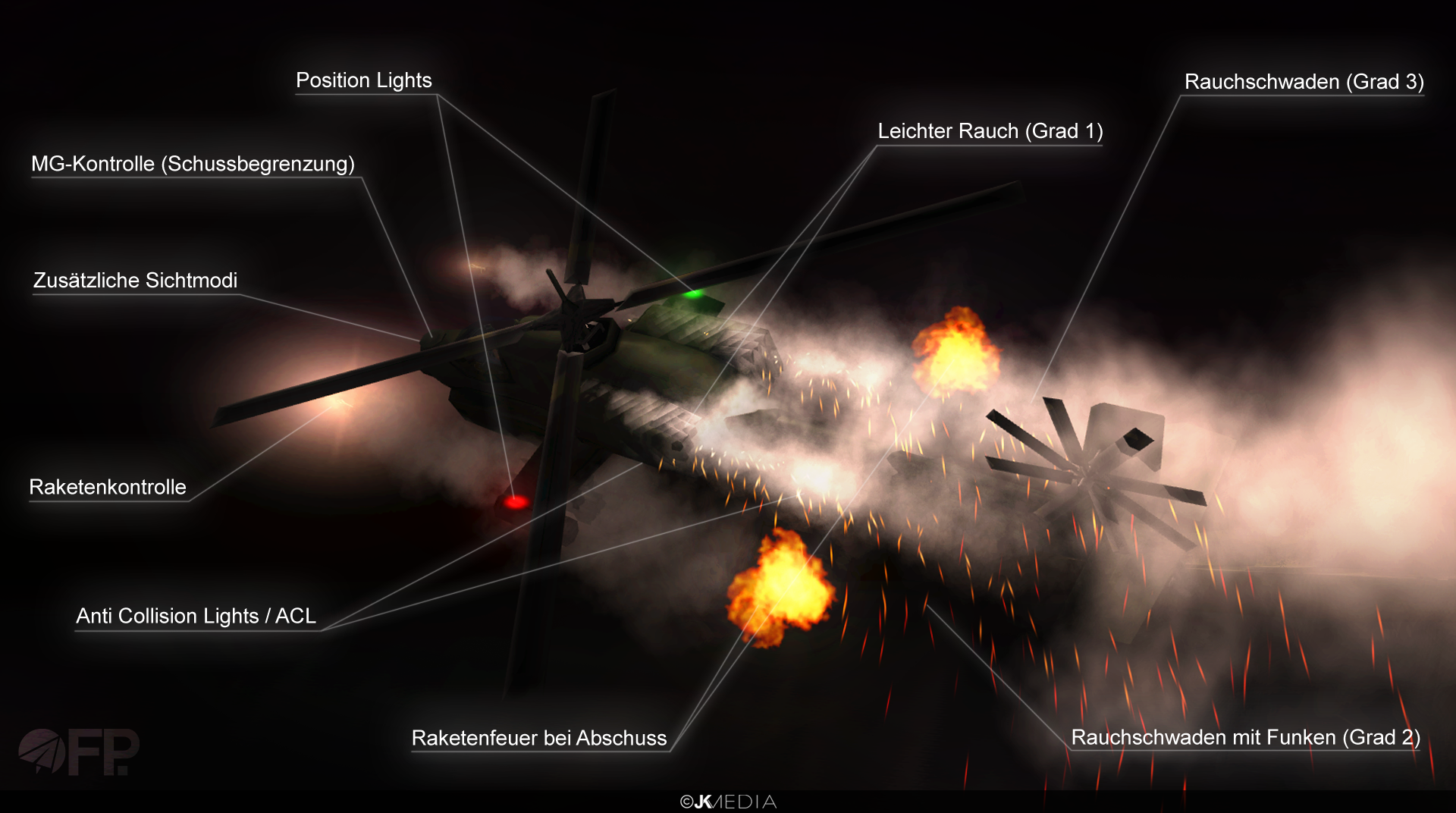

Upon request of a video game multiplayer server, the German Public Server, I created an own so called “mod” for its community to improve their gameplay’s quality. My goal was to make it more fun using in-game aircraft, such as planes and helicopters.

The original game Grand Theft Auto San Andreas already provides a thrilling experience when flying, however, all aircraft lacked visible position and flashing lights like we know them from real planes. When damaged, the vehicles produce the same type and amount of smoke, which made it look cheap quickly. Guns and weapons had the same optical deficiency.

Flight Pack changed this – For all 17 game aircraft vehicles, new unique and interactive features got implemented. Before I could place new entities like lights or effect sources, each vehicle had to be analyzed first to find the right coordinates for those add-ons, respecting the relation to the aircraft’s orientation. Having all vehicles with different structures led to sheets of data.

Lua unleashed

It took about 2,000 lines of Lua code to program Flight Pack. Having to deal with a linkage between local players and an online server was new to me, splitting the code into two pieces: The client’s side, and the server’s side. Live test runs with other players were inevitable to find problematic bugs and hidden errors, since not every scenario could be simulated all by myself locally.

MAP ADD-ONS – EXPANDING THE WORLD:

Before I worked on Flight Pack, the same server asked me to create an expansion for the original world of the game, meaning setting up new towns, new forests, new roads and new features for the server’s community to explore. This add-on should also attract new players, hence producing more traffic and therefore putting the server on a better ranking list globally.

Around 800 objects from the game have been isolated, copied and replaced to create the expansion, mostly by setting three coordinates plus three orientation parameters precisely for each object. With Lua code, special interactive functions have been scattered all around the territory in addition, to make the new land even more intriguing.

Placing objects within MEd

WATCH HOW I PROMOTED THIS SERVER BY FILM:

3D PRINTING – DO IT YOURSELF 2.0

When working for TDK, our department purchased a 3D-printer to produce and test new bobbin prototypes. In order to do so, it was required to prepare all CAD-models for additive printing beforehand. Depending on the individual filament being used, different parameters (such as nozzle speed, fan cooling, density and temperature) had to be adjusted carefully to ensure the success of the printing process. Since the nozzle always needs something to print on, support structures were added, which you also must tune manually.

Wrong settings deteriorate general adhesion, leading to false formations, or to non-removable support structures. It can take much time to find the right combination of all values before actually achieving a good print. Undeniably, experimenting and gaining experience with new and unknown materials ask for a lot of persistence and patience. Especially when printing times exceed several hours – Only to result in a severe failure in some cases right before completion.

From scratch

Sometimes our laboratory needed special items or pieces for preparing individual experiments. Objects which can be 3D-printed, but which also lack the necessary CAD-file. Since CAD-specialists were not always available, I took the time to create some models myself with the help of FreeCAD. The image seen here shows some parameters from one of three axis views.

When the CAD-file is finally prepared for printing, it needs to be converted into a code which the printer system can read. From then on, observing the printing process carefully might be essential to spot critical spots right in time. Seeing how the material behaves during printing can help later with optimizing all parameters.

Good maintenance of the printer itself has also a crucial effect on the print’s quality. Disassembling, cleaning, fixing and replacing worn parts turned out to be just as important as keeping all other tools from the laboratory in good shape.